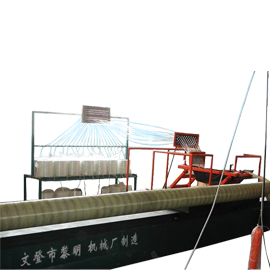

FRP Winding Process

Wrapped glass fiber reinforced plastic is a kind of glass fiber forming process, this method is the opposite of the lathe cutting workpiece.

The definition of the winding process: through the rotation of the core mold, the guide wire according to a certain trajectory movement, fully impregnated resin continuous glass fiber through the wire head and the regular winding on the core mold, until the thickness of the design requirements so far.

The characteristics of the winding process:

1, wrapped glass fiber reinforced plastic than the strength of three times higher than ordinary steel, titanium is four times. Higher than the high strength of this feature in the aviation application value is obvious.

2, winding product quality and production of high efficiency, easy to mass production of mechanized, easy to achieve mechanization and automation.

3, Woven fiberglass products used in fiber reinforced materials without textile, can reduce the textile process, thereby reducing costs.

4, winding process for corrosion-resistant pipes, tanks and high-pressure pipe, container manufacturing, which is less than other processes.

Welded glass pipe classification:

1, according to the production process can be divided into two categories, namely the process pipeline and sand pipe;

2, according to its use and material can be divided into food grade pipeline, acid pipe, alkali pipe, high temperature pipe, high pressure pipe.

Process:

Preparation → lining → curing → winding → curing → dressing → stripping

Preparation: Preparation of raw and auxiliary materials and mold, testing equipment in good condition.

Lining: laying in accordance with the lining system, layer by layer and meet the process requirements.

Curing: core mold rotation, infrared heating curing.

Winding: through the computer control, will be impregnated resin continuous glass fiber yarn has been made in the lining of the mold, and to meet its technological requirements.

Dressing: trim the socket according to the dressing requirements.

Stripping: Separate and trim the pipe from the mold.