Full thread resin glass fiber reinforced plastic rod, is made of high-performance resin and high-strength glass fiber, supplemented by a variety of additives, and then processed by a special process of composite materials. Because of its special material, suitable for mine roadway construction, and then will gradually replace the traditional metal bolt. Also known as glass fiber anchor or fiberglass anchor. National Coal Mine Product Safety Certification Center has been approved in the use of coal and comprehensive promotion.

Compared with the metal anchor, the advantages of glass steel anchor are the following:

Easy cutting of the rod: FRP anchor for the composite material is easy to cut, can play a protective role of the cutter head;

Explosion-proof anti-static: cutting will not produce sparks, the roadway safety construction is extremely beneficial, especially for high gas areas;

High strength corrosion resistance: high load capacity, tensile strength, rod strength is better than equal diameter rebar, can be used as long support;

Light and easy to operate: Construction methods and metal rods the same, but the weight is only the same specifications of metal anchor 1/4. Can be used in tunnels and coal mines and other small space to facilitate the use; to make the construction easier, so as to reduce the labor intensity of workers to improve labor efficiency.

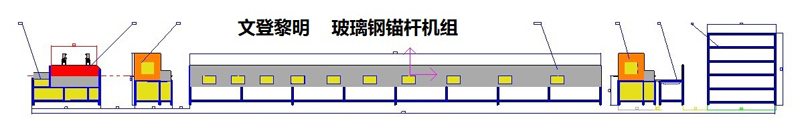

I research and development, production and sales of the world's leading level of full-threaded glass steel bolt production line.

The production line set at home and abroad and the integration of its own unique technology, with advanced technology, reliable performance and so on.

The main advantages of the production line: high production efficiency (3000-6000mm / min, 2-3 times the general equipment); saving material costs (can be reduced by 10-30%); saving process costs (1-3 yuan / m); automation (4 people / 2 production line); environmentally friendly low energy consumption.

Companies can match for a variety of different nuts and pallet processing equipment (including high-strength non-metallic nuts, trays carrying capacity ≥ 150KN).

Bolt equipment and products Advantages:

First, a molding: rod. Mother matching

Second, the speed: 3-6 meters per minute

Third, the torque: 50-130 above customized according to customer needs

Fourth, carrying large: tray, screw is the company's patented product

5, continuous production time: 72 hours

Six, low cost: down 2-4 yuan per meter

Seven, easy to purchase raw materials

Eight, the formula scientific and reasonable

Nine, life service: simple maintenance

The main performance indicators (to JKG60-20 as an example)

Project Unit Industry Standard Enterprise Standard

Rod tensile strength Mpa ≥ 244 ≥ 680

Rod shear strength Mpa ≥ 75 ≥ 110

Torque N · m ≥ 40 ≥45

Anchoring force kN ≥ 68.6 ≥215

Tail connection and thread bearing capacity kN ≥68.6 ≥140

Tray bearing capacity kN ≥ 68.6 ≥125